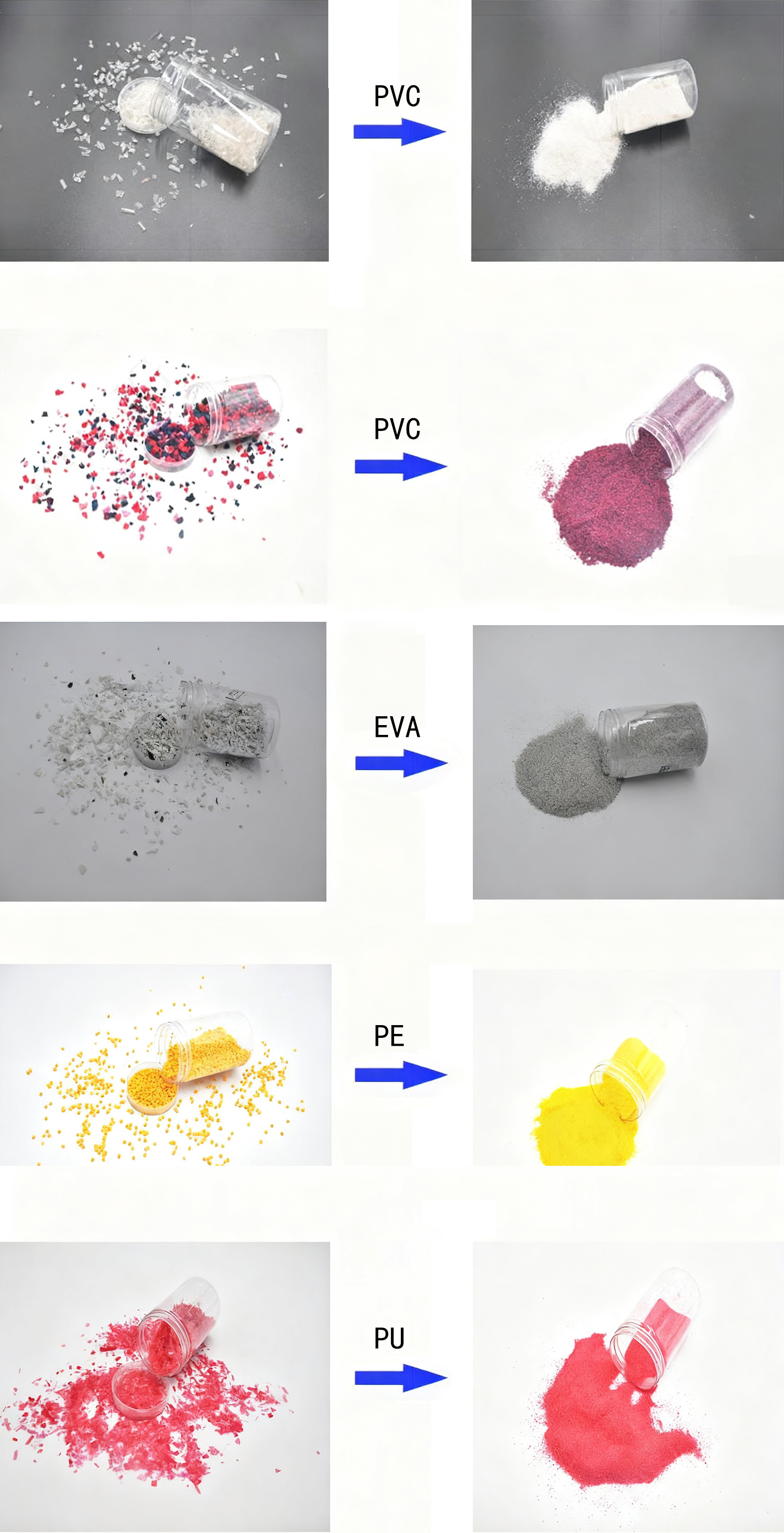

The Model 1000 PVC Pulverizer is a high-capacity powder processing machine designed for large-scale plastics recycling plants, large chemical companies, and renewable resource parks. It is primarily used for the intensive grinding and recycling of bulk plastics such as PVC, PE, and PP. With its extra-large grinding disc (1000mm diameter) and high-power drive system, this machine can process large waste materials such as PVC pipes, wide plastic-steel profiles, and thick-walled plastic sheets. It is also compatible with pulverizing non-plastic materials such as rubber, wood, and leather, enabling multi-material applications.

The Model 1000 PVC Pulverizer is a high-capacity powder processing machine designed for large-scale plastics recycling plants, large chemical companies, and renewable resource parks. It is primarily used for the intensive grinding and recycling of bulk plastics such as PVC, PE, and PP. With its extra-large grinding disc (1000mm diameter) and high-power drive system, this machine can process large waste materials such as PVC pipes,wide plastic-steel profiles, and thick-walled plastic sheets. It is also compatible with pulverizing non-plastic materials such as rubber, wood, and leather, enabling multi-material applications.

The machine boasts a production capacity of 800-1500 kg/h and is equipped with an intelligent control system that optimizes feed rate, grinding speed, and dust removal efficiency, ensuring consistent powder quality during continuous operation. Its reinforced rotor and wear-resistant liner significantly enhance its handling capacity for high-hardness and high-impurity waste. It serves a wide range of applications in waste plastic centralized processing centers, front-end powder preparation at plastic masterbatch production bases, and plastic recycling lines at municipal waste sorting centers.

01 Precise Classification and High Powder Purity:The equipment’s grading device (as evidenced by the complex screening structure in the image) precisely grades and screens the ground PVC powder, effectively separating powders of varying particle sizes and removing impurities. This ensures the high purity of the output powder, meeting the stringent requirements of downstream production processes, such as the raw material preparation for high-end PVC products.

02

Excellent Heat Dissipation and Reliable Operation: The equipment’s structural layout (including appropriate spacing between components and heat dissipation design for power components) demonstrates excellent heat dissipation. This allows for rapid heat dissipation during long, high-speed grinding operations, preventing equipment failures caused by overheating. This ensures reliable and stable operation and reduces the need for maintenance downtime.

03 Smooth Feeding and Excellent Anti-clogging:

Smooth Feeding and Excellent Anti-clogging

The rational design of the feed inlet and associated conveying mechanisms ensures smooth entry of PVC material into the grinding chamber. During the grinding process, the unique chamber design effectively prevents material blockage, ensuring a continuous grinding process, improving overall production efficiency, and reducing cleanup time and material waste caused by blockages.

04

Excellent Sealing Performance and Low Powder Leakage:The equipment’s excellent sealing design at all joints (such as pipe connections and the grinding chamber cover) effectively prevents powder leakage during the grinding process. This not only maintains a clean production environment and reduces dust pollution, but also reduces material loss, improves raw material utilization, and saves production costs for enterprises.

| Mode | Type 400 | Type 600 | Type 800 | Type 1000 |

|---|---|---|---|---|

| Cutter diameter | 400mm | 600mm | 800mm | 1000mm |

| Number of cutter discs | 18 piece | 28 piece | 36 piece | 42 piece |

| Motor power | 18 – 30KW | 45 – 55KW | 75 – 90KW | 90 – 110KW |

| Speed | 3900(r/min) | 3600(r/min) | 2800(r/min) | 2600(r/min) |

| Suction fan | 2.2 – 3KW | 4.5KW | 5.5 – 11KW | 7.5 – 15KW |

| Fan off | 0.75(KW) | 1.1(KW) | 1.5(KW) | 1.5(KW) |

| Vibrating screen | 0.55KW600 | 1.1KW1000 | 1.1KW1200 | 1.5KW1500 |

| Mill water | circulating water | circulating water | circulating water | circulating water |

| Grinding capacity | 80 – 150(Kg/h) | 200 – 400(Kg/h) | 600 – 1000(Kg/h) | 800 – 1500(Kg/h) |

| Installation dimensions | 220013003000(mm) | 300018003500(mm) | 320018003700(mm) | 350018003800(mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|