The 800 PVC pulverizer is a versatile medium-to-large-scale powder processing machine suitable for large-scale grinding of a variety of plastic and rubber materials, including PVC, PE, PS, ABS, EVA, PET, SBS, and SEBS. It is widely used in industries such as chemicals, waste recycling, plastic modification, and wood-plastic composites. This machine specializes in processing high-hardness and high-toughness materials, efficiently pulverizing PVC pipe/profile scrap, expanded PE/EPS insulation boards, ABS electrical housings, and PPR pipe scraps. It is particularly adept at processing thick-walled plastic parts and fiber-reinforced composites.

The 800 PVC pulverizer is a versatile medium-to-large-scale powder processing machine suitable for large-scale grinding of a variety of plastic and rubber materials, including PVC, PE, PS, ABS, EVA, PET, SBS, and SEBS. It is widely used in industries such as chemicals, waste recycling, plastic modification, and wood-plastic composites. This machine specializes in processing high-hardness and high-toughness materials, efficiently pulverizing PVC pipe/profile scrap, expanded PE/EPS insulation boards, ABS electrical housings, and PPR pipe scraps. It is particularly adept at processing thick-walled plastic parts and fiber-reinforced composites.

With a production capacity of 200-400 kg/h, the Model 600 meets diverse needs, from coarse powder filling to fine modification. It can be widely used in scrap recycling lines of pipe and profile factories, decorative material factories, and in the early stages of powder preparation for recycled plastic pellet manufacturers.

01

01

Fine Grinding, High-Quality Powder:The machine’s precision-engineered grinding components enable deep and uniform grinding of materials like PVC. The resulting powder boasts a fine and evenly distributed particle size, meeting stringent powder quality requirements in subsequent processes such as plastic modification and high-end product production, enhancing the performance and quality of the final product.

02

Intelligent Control, Stable Operation: Equipped with an advanced intelligent control system, it precisely adjusts parameters such as feed rate and grinding pressure, automatically adapting to optimal operating conditions based on different material characteristics and grinding requirements. This ensures stable operation over extended periods, reduces failures caused by improper parameters, and ensures continuous production.

03

03

Energy Saving and Consumption Reduction, Low Operating Costs: By optimizing the power system and mechanical transmission structure, the machine effectively reduces energy consumption while maintaining grinding efficiency. Compared to traditional grinding equipment, this system can save businesses significant amounts of electricity and other energy costs, significantly reducing production and operating costs over time.

04

Easy Maintenance and Long Service Life:Key components are constructed from wear- and corrosion-resistant materials, and the overall modular design allows for easy assembly and disassembly of components, facilitating daily cleaning, maintenance, and upkeep. This effectively extends the equipment’s service life and reduces production downtime due to equipment failure or component replacement.

| Mode | Type 400 | Type 600 | Type 800 | Type 1000 |

|---|---|---|---|---|

| Cutter diameter | 400mm | 600mm | 800mm | 1000mm |

| Number of cutter discs | 18 piece | 28 piece | 36 piece | 42 piece |

| Motor power | 18 – 30KW | 45 – 55KW | 75 – 90KW | 90 – 110KW |

| Speed | 3900(r/min) | 3600(r/min) | 2800(r/min) | 2600(r/min) |

| Suction fan | 2.2 – 3KW | 4.5KW | 5.5 – 11KW | 7.5 – 15KW |

| Fan off | 0.75(KW) | 1.1(KW) | 1.5(KW) | 1.5(KW) |

| Vibrating screen | 0.55KW600 | 1.1KW1000 | 1.1KW1200 | 1.5KW1500 |

| Mill water | circulating water | circulating water | circulating water | circulating water |

| Grinding capacity | 80 – 150(Kg/h) | 200 – 400(Kg/h) | 600 – 1000(Kg/h) | 800 – 1500(Kg/h) |

| Installation dimensions | 220013003000(mm) | 300018003500(mm) | 320018003700(mm) | 350018003800(mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q1: Do you customize products for customers?

A1: Yes, we can customize and produce crushing machinery according to customers’ requirements or drawings.

Q2: How about the quality of your products?

A2: We can provide you with samples for quality inspection. If you order, we guarantee the same quality as the sample. If there is a quality problem, we can sign an agreement and let our company perform the duties.

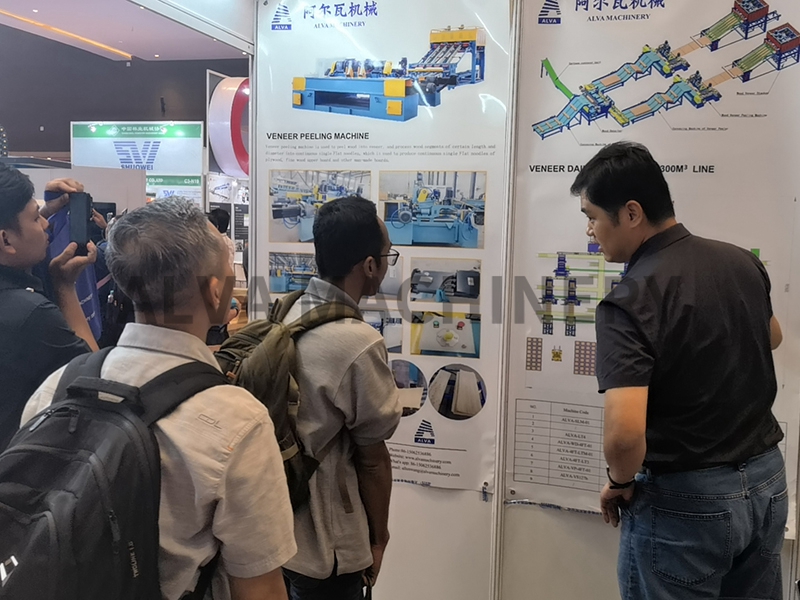

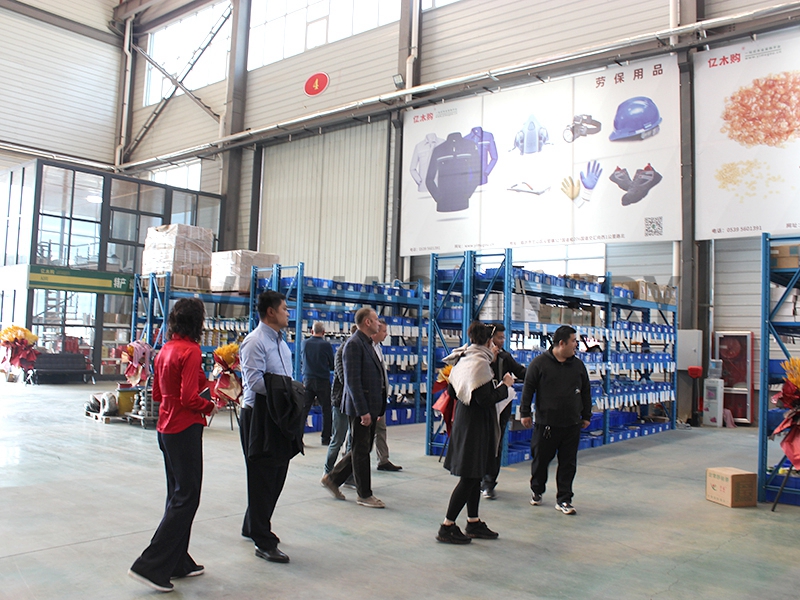

Q3: How can we trust your factory?

A3: We suggest that you come to our factory to see the goods, verify the real situation of the products, and learn more about our factory.

Q4: Why do prices change so often?

A4: The price depends on the latest prices of raw materials.

Q5: What about contract signing?

A5: If you are satisfied with the product and our service, you can sign a contract with us, pay a deposit, and then we will produce the machine as soon as possible. If you are far away, we can sign the contract by fax. We will ensure the quality of products and accessories complete.

Q6: What about delivery?

A6: When the product is ready, it will be delivered to you after full payment. Technical guidance will be provided.