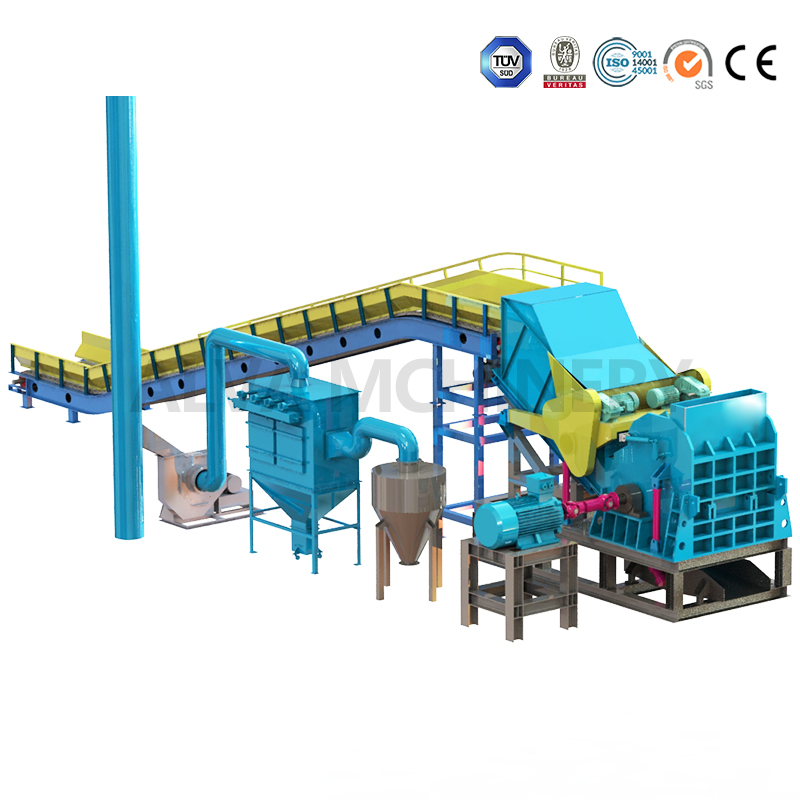

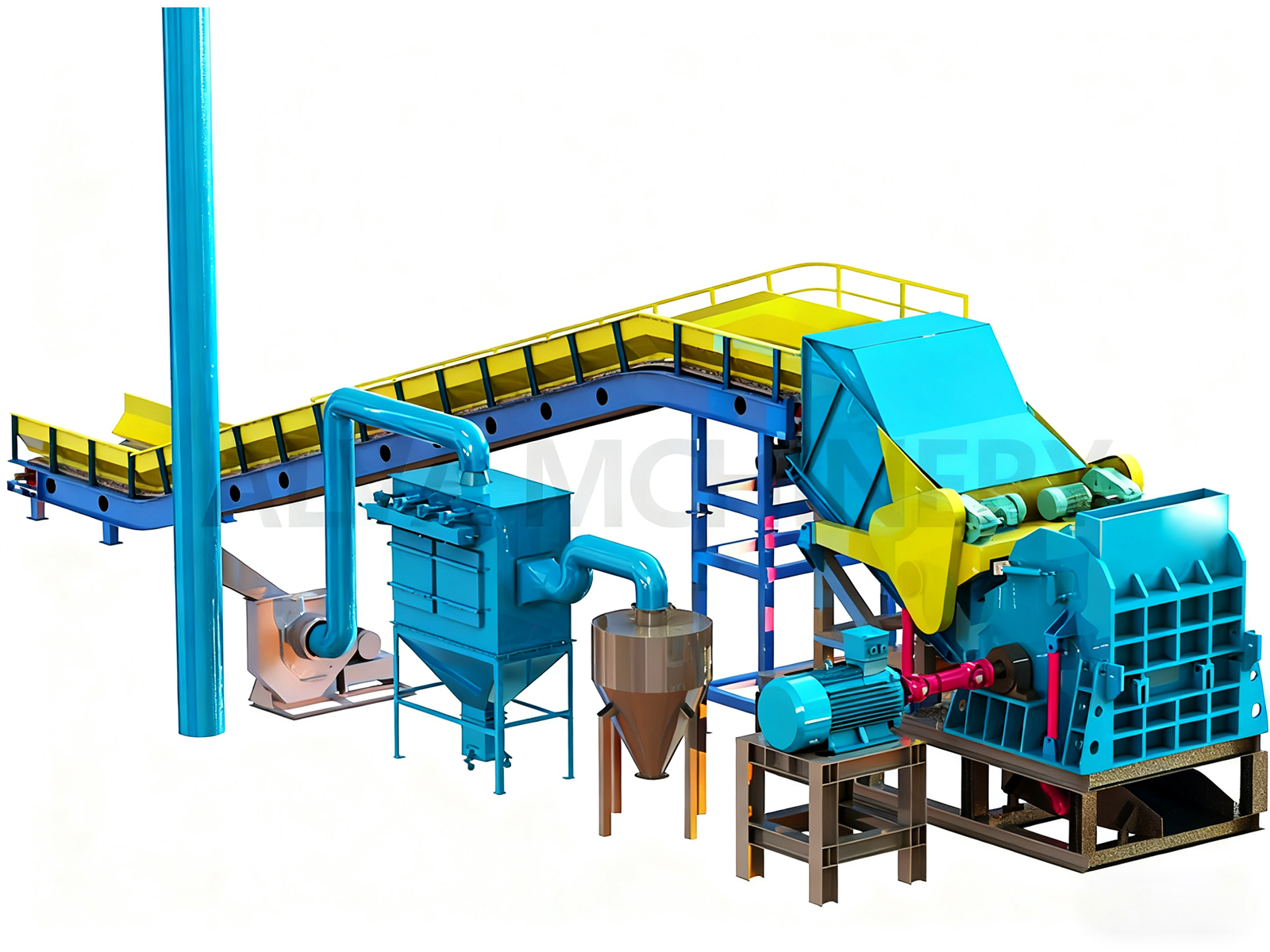

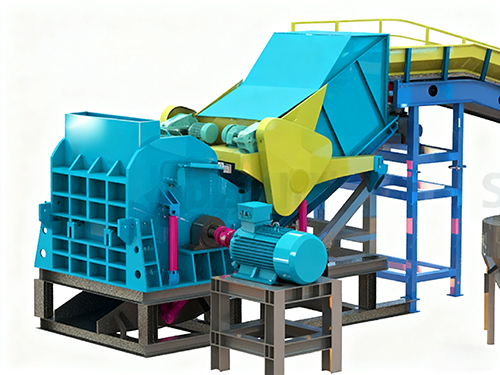

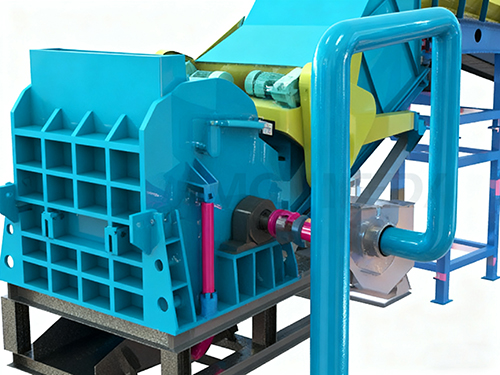

The 200 metal shredder is designed for medium-sized batch crushing applications and is widely used in small and medium-sized scrap steel recycling centers and foundries for metal recycling. It efficiently crushes medium-thick metal materials such as scrap steel plates, bearing seats, and motorcycle frames. Equipped with a 30-45kW motor and a feed port measuring 400×450mm, it boasts a stable crushing capacity of 3-5 tons per hour. The crushing chamber features a multi-tooth liner design and 12 sets of reversible hammers, achieving a multi-step crushing process of “impact-compression-shearing.” Even 10mm thick steel plates can be crushed into shape in one operation. The machine features a hydraulic cover opening, allowing for hammer replacement and chamber cleaning in just 30 minutes, ensuring both efficient production and environmental protection.

01

01

Heavy-duty construction, stable and durable.

The 16-20mm thick steel plate welded construction features a reinforced frame and bearing housing, and an independent shock-absorbing base. Operating noise is ≤85dB, with an average trouble-free operation time exceeding 10,000 hours, making it suitable for continuous, high-intensity production.

02

Stable conveyor belt load and conveying capacity: A single conveyor belt can transport 2-8 tons per hour, suitable for a variety of metal materials such as scrap steel, aluminum alloy blocks, and auto parts. It can operate continuously at high intensity 24 hours a day, perfectly matching the crushing efficiency of the metal shredder.

03

03

Versatile adaptability, versatile application scenarios.

The wide feed port is compatible with various materials, including scrap home appliances and automotive parts. Equipped with an adjustable 8-50mm screen, material specifications can be customized to meet downstream needs such as smelting and recycling granulation.

04

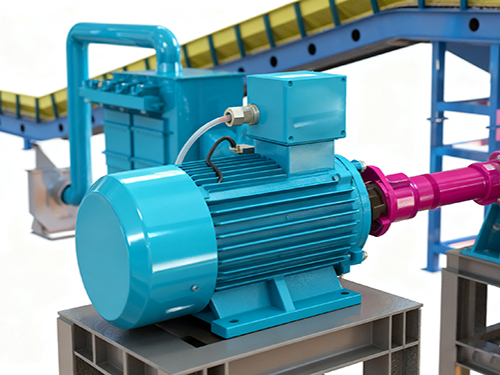

High-efficiency motor configuration, stable power output

Utilizing a national standard Y series three-phase asynchronous motor with a power range of 15-75kW, the motor’s power parameters are precisely matched to the equipment model, achieving an efficiency of over 92%, saving 12% energy compared to conventional motors. This reduces power transmission losses and ensures a continuous and stable crushing process.

| Model | Feed Size (mm) | Production Capacity | Energy Consumption | Energy Consumption | Load Bearing | External Dimensions | External Dimensions | External Dimensions | External Dimensions |

| Monolithic Output (th) | Fan Motor Power (kW) | Distribution Transformer Requirements (kVA) | Weight (kg) | Length (L, m) | Width (W, m) | Height (H, m) | Floor Area (㎡) | ||

| ALVA-MCM-75 | 900 | 1 | 75 | 125 | 5 | 4 | 3.7 | 3 | 12 |

| ALWA-MOM-110 | 1000 | 1.5 | 110 | 160 | 11 | 4 | 4 | 3.5 | 96 |

| ALWA-MOM-132 | 1260 | 2 | 132 | 200 | 16 | 4.5 | 4.8 | 3.5 | 140 |

| ALMW-MOM-160 | 1460 | 3-4 | 160 | 250 | 26 | 5 | 4.9 | 3.5 | 160 |

| ALVA-MCM-200 | 1500 | 4-5 | 200 | 315 | 35 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-315 | 1600 | 6-7 | 315 | 500 | 40 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-450 | 1600 | 8-9 | 450 | 630 | 55 | 7 | 4.9 | 4 | 300 |

| ALVA-MCM-630 | 1800 | 10-11 | 630 | 10,000 | 75 | 7.5 | 6 | 4 | 400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|