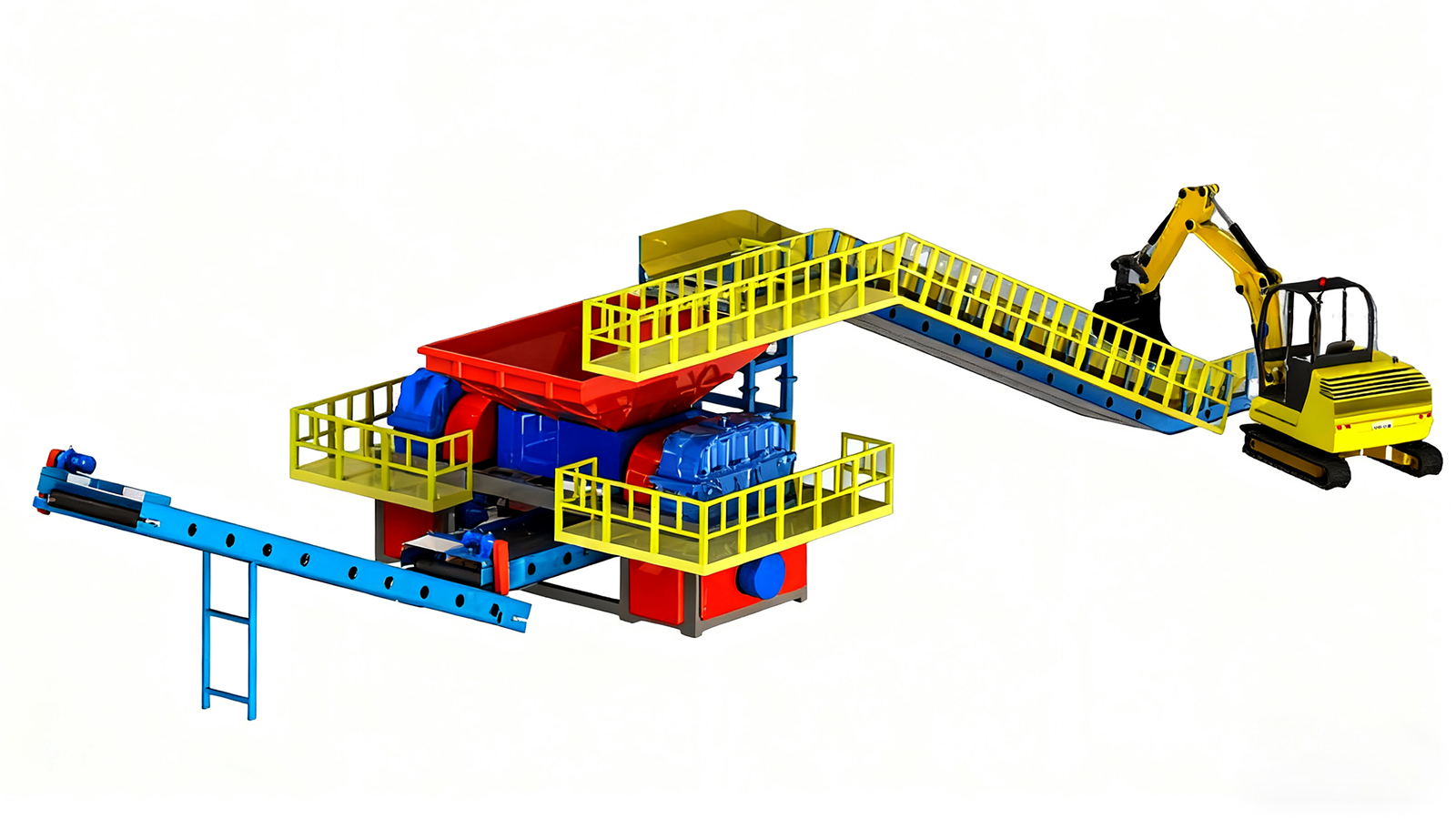

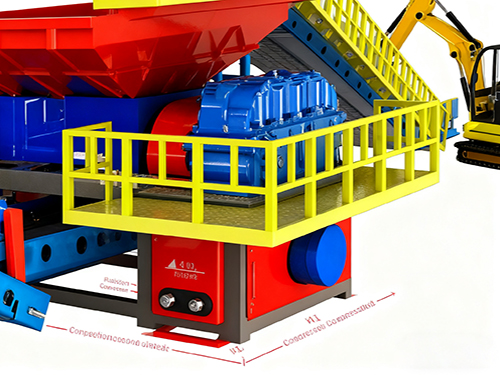

The 315 metal shredder is Alva’s mid-sized, industrial-grade workhorse, designed for regional scrap recycling centers and steel mill waste processing plants. It’s suitable for crushing heavy metal materials such as automobile hulls, machine tool beds, and large pipes. Equipped with a high-power 55-75kW motor and an expanded feed port size of 500×600mm, it can crush 5-8 tons of material per hour. For scrap materials under 15mm thick, the crushed particle size can be adjusted to 30-80mm using a screen, meeting feed standards for blast furnace smelting or electric furnace reuse. The 315 features a one-piece welded frame, offering a 40% increase in load-bearing strength compared to conventional models. Combined with an intelligent temperature control system and automatic lubrication replenishment system, it can operate continuously 24 hours a day, with an overall equipment failure rate of less than 0.5%.

01

01

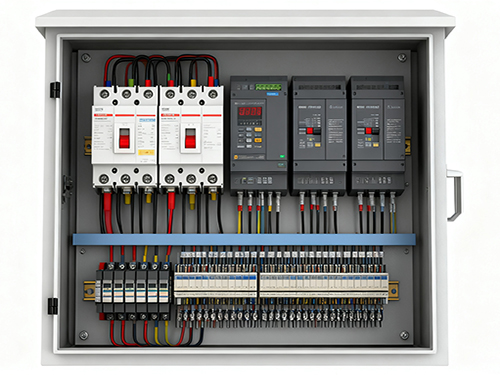

Intelligent and precise control: The CNC cabinet is equipped with an advanced PLC control system, integrating multiple functions such as automated control, fault diagnosis, and parameter adjustment. Operators can precisely set crusher operating parameters such as crushing speed, feed rate, and motor power via the touchscreen or remote control terminal, achieving precise control of the crushing process and ensuring consistent and stable crushing results.

02

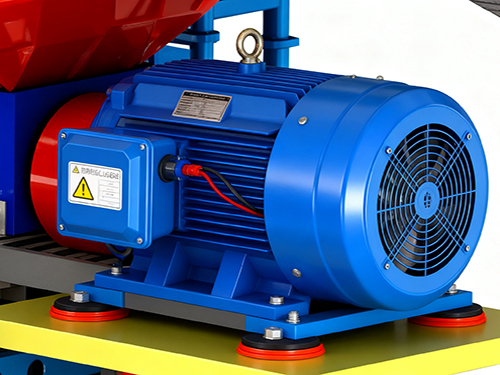

Powerful power and energy efficiency: Equipped with a high-performance three-phase asynchronous motor, with a power range of 30-200kW depending on the model and crushing requirements, it provides powerful and stable power output, ensuring effective crushing of metals of various hardnesses and materials. The motor utilizes advanced electromagnetic design and manufacturing processes, achieving an efficiency of over 95%. This saves over 20% energy compared to traditional motors, reducing equipment operating costs.

03

03

Large-size design and efficient feeding: The feed opening features a large opening, customizable to meet specific needs. It easily accommodates large metal scrap, such as used auto parts and large-sized steel bars, reducing material pre-treatment requirements and improving feeding efficiency. Furthermore, the carefully designed angle of the feed opening, combined with the conveyor belt, ensures fast and smooth material feeding, reducing the risk of blockage and ensuring high-capacity operation.

04

Rugged and Durable Structure: The machine body is welded from high-quality steel and undergoes rigorous heat treatment and stress relief processes, resulting in exceptional strength and rigidity to withstand the immense impact and vibration generated during the crushing process. Key areas of the frame are reinforced, and welds are inspected for flaw detection, ensuring structural reliability and stability, ensuring a service life of over 10 years.

| Model | Feed Size (mm) | Production Capacity | Energy Consumption | Energy Consumption | Load Bearing | External Dimensions | External Dimensions | External Dimensions | External Dimensions |

| Monolithic Output (th) | Fan Motor Power (kW) | Distribution Transformer Requirements (kVA) | Weight (kg) | Length (L, m) | Width (W, m) | Height (H, m) | Floor Area (㎡) | ||

| ALVA-MCM-75 | 900 | 1 | 75 | 125 | 5 | 4 | 3.7 | 3 | 12 |

| ALWA-MOM-110 | 1000 | 1.5 | 110 | 160 | 11 | 4 | 4 | 3.5 | 96 |

| ALWA-MOM-132 | 1260 | 2 | 132 | 200 | 16 | 4.5 | 4.8 | 3.5 | 140 |

| ALMW-MOM-160 | 1460 | 3-4 | 160 | 250 | 26 | 5 | 4.9 | 3.5 | 160 |

| ALVA-MCM-200 | 1500 | 4-5 | 200 | 315 | 35 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-315 | 1600 | 6-7 | 315 | 500 | 40 | 6 | 4.9 | 3.5 | 250 |

| ALVA-MCM-450 | 1600 | 8-9 | 450 | 630 | 55 | 7 | 4.9 | 4 | 300 |

| ALVA-MCM-630 | 1800 | 10-11 | 630 | 10,000 | 75 | 7.5 | 6 | 4 | 400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|