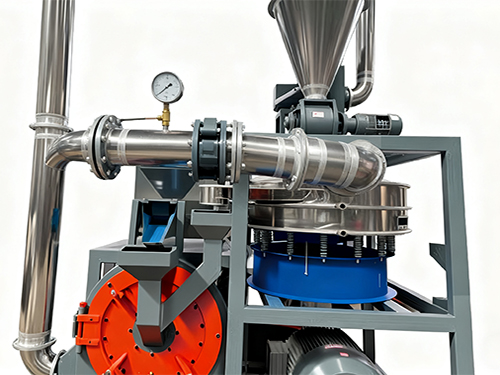

The Model 600 PVC pulverizer is an automated processing machine designed for the recycling of medium-volume rigid PVC scrap. Its primary application is in the waste recycling systems of the plastics chemical industry and PVC product manufacturers. This machine specializes in processing rigid materials such as PVC small white pipes, plastic-steel door and window profiles, skirting boards, decorative moldings, plasterboards, and plaster pipes. It is also compatible with the pulverization and recycling of new, environmentally friendly materials such as SPC flooring and WPC wood-plastic composites.

The Model 600 PVC pulverizer is an automated processing machine designed for the recycling of medium-volume rigid PVC scrap.

Its primary application is in the waste recycling systems of the plastics chemical industry and PVC product manufacturers.

This machine specializes in processing rigid materials such as PVC small white pipes, plastic-steel door and window profiles,

skirting boards, decorative moldings, plasterboards, and plaster pipes. It is also compatible with the pulverization and recycling

of new, environmentally friendly materials such as SPC flooring and WPC wood-plastic composites.

With a production capacity of 200-400 kg/h, the Model 600 meets diverse needs, from coarse powder filling to fine modification.

It can be widely used in scrap recycling lines of pipe and profile factories, decorative material factories, and in the early stages

of powder preparation for recycled plastic pellet manufacturers.

01

01

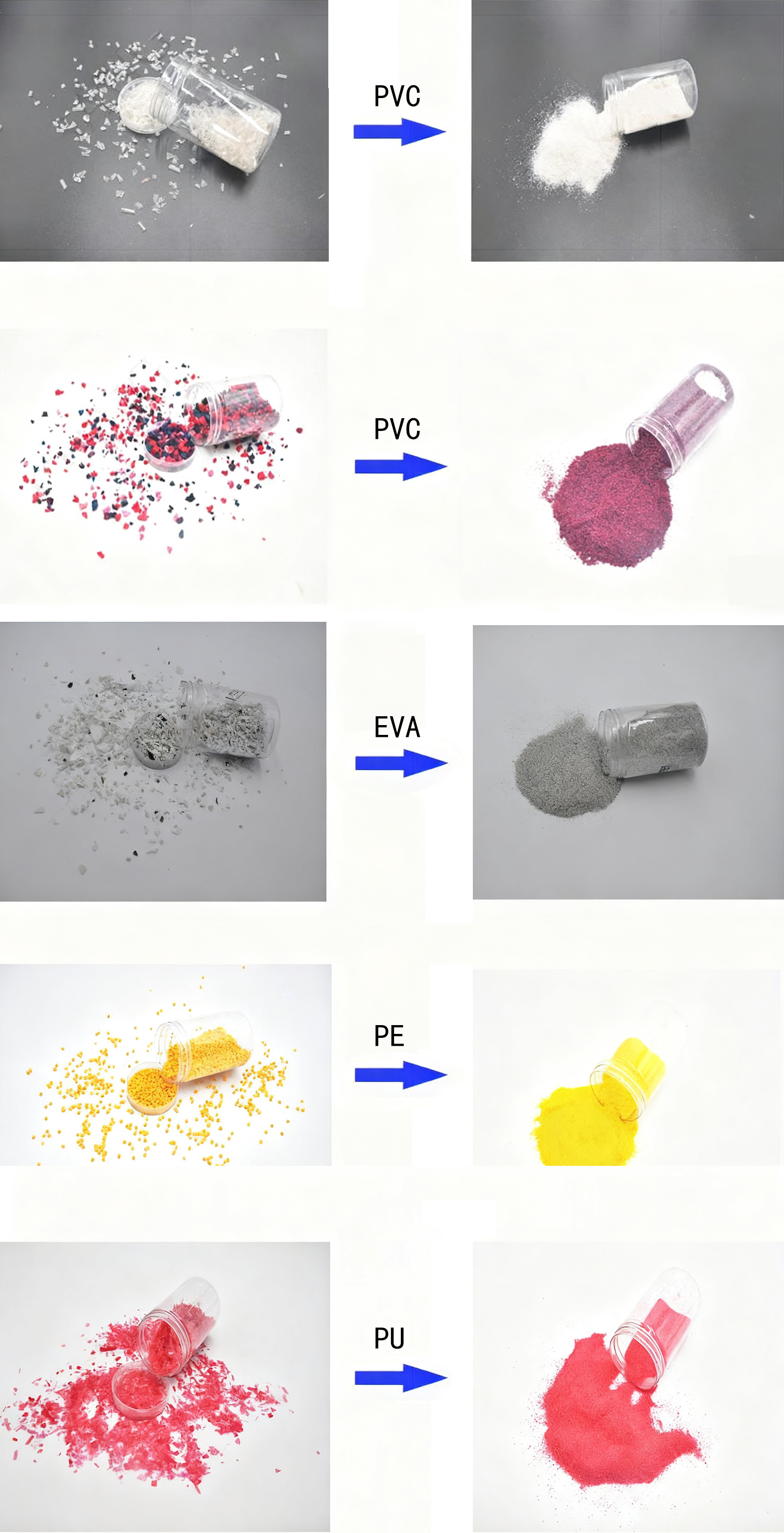

Wide Material Adaptability:This PVC grinding mill not only efficiently processes various types of PVC waste but is also compatible with a variety of plastic materials, such as PE, PS, and PA, meeting the needs of diverse plastic recycling and processing scenarios, providing strong support for companies to expand their raw material sources and improve resource utilization.

02

Intelligent and Precise Control: Equipped with an advanced intelligent control system, it precisely adjusts parameters such as feed rate and grinding speed, ensuring stable grinding and consistent powder quality under varying operating conditions. This reduces manual operation errors and enhances intelligent and controllable production.

03

03

Excellent Wear Resistance: Core grinding components are made of highly wear-resistant materials to withstand long-term, high-intensity material grinding operations, effectively extending equipment life, reducing maintenance costs and downtime caused by component wear, and ensuring continuous production.

04

Significant Energy Savings: By optimizing the power system and mechanical structure, energy consumption is significantly reduced while maintaining grinding efficiency. Compared to traditional grinding equipment, this can significantly save companies significant electricity costs, aligning with the production trend of energy conservation and consumption reduction.

| Mode | Type 400 | Type 600 | Type 800 | Type 1000 |

|---|---|---|---|---|

| Cutter diameter | 400mm | 600mm | 800mm | 1000mm |

| Number of cutter discs | 18 piece | 28 piece | 36 piece | 42 piece |

| Motor power | 18 – 30KW | 45 – 55KW | 75 – 90KW | 90 – 110KW |

| Speed | 3900(r/min) | 3600(r/min) | 2800(r/min) | 2600(r/min) |

| Suction fan | 2.2 – 3KW | 4.5KW | 5.5 – 11KW | 7.5 – 15KW |

| Fan off | 0.75(KW) | 1.1(KW) | 1.5(KW) | 1.5(KW) |

| Vibrating screen | 0.55KW600 | 1.1KW1000 | 1.1KW1200 | 1.5KW1500 |

| Mill water | circulating water | circulating water | circulating water | circulating water |

| Grinding capacity | 80 – 150(Kg/h) | 200 – 400(Kg/h) | 600 – 1000(Kg/h) | 800 – 1500(Kg/h) |

| Installation dimensions | 220013003000(mm) | 300018003500(mm) | 320018003700(mm) | 350018003800(mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|