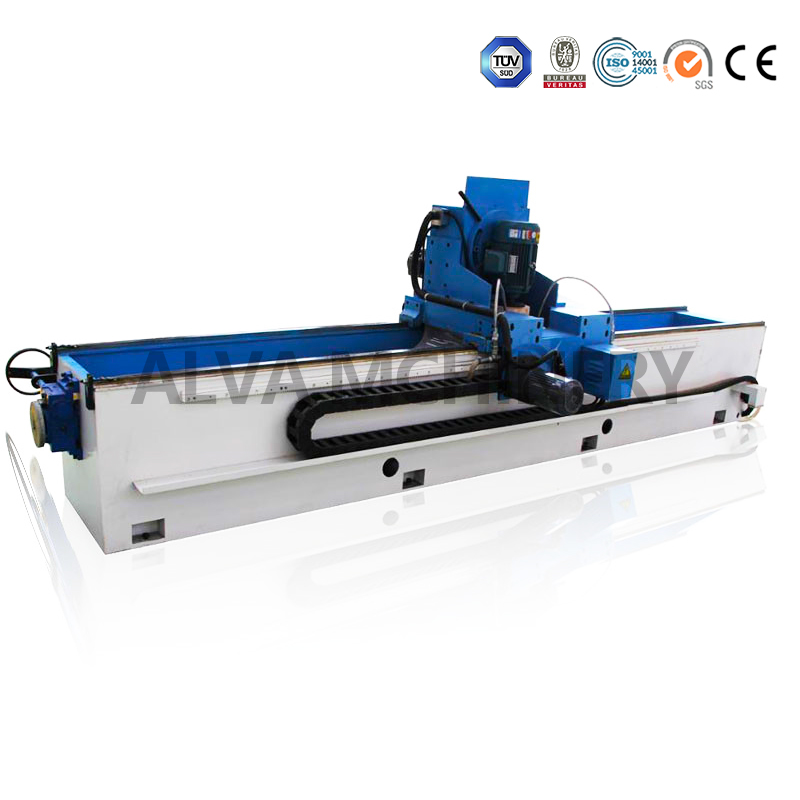

ALVA proudly presents the Precision Automatic Sharpener Grinding Machine. This new model, developed by absorbing advanced technologies from home and abroad, features a high-precision feeding mechanism. It ensures minimal errors in grinding angle and size, making it essential for sharpening various knife plates. Easy to operate, this Automatic Grinding Machine is a top choice for wood processing businesses.

Shandong Alva Machinery Co., Ltd. has focused on the woodworking machinery field for 30 years. Adhering to the corporate tenet of “Creating value for customers and benefits for partners”, the company takes “Product quality is produced, not inspected” as its core business philosophy. Every product undergoes research and development, practical application and strict quality inspection.

With reliable quality, its products have passed multiple international authoritative certifications including CE and SGS, and are sold well in both domestic and foreign markets. They not only occupy a significant position in the domestic woodworking machinery sector, but also successfully completed the installation and commissioning of veneer peeling machine production lines in Vietnam and other regions, helping local enterprises enhance their production capacity and market competitiveness.

Meanwhile, the company has established a comprehensive service system, providing services such as overseas equipment installation and commissioning, operator training, and 24-hour online consultation. Both the whole machine and key components are covered by warranty, with the after-sales team responding within 48 hours. In addition, the company offers product customization and personalized packaging services to fully meet the needs of customers at home and abroad.

The knife sharpener is equipped with a high-precision feeding mechanism, which can ensure that the angle and size error of each sharpening are controlled within a very small range, so that the rotary cutter tool maintains a precise cutting angle, ensuring that the thickness of the wood chips cut out is uniform and the surface is smooth.

The Alva knife sharpener is easy to operate. The staff only needs to enter simple parameters, such as sharpening angle, grinding amount, etc., to automatically complete the sharpening process, without complex operating skills and experience, reducing labor costs and operating difficulties.

02

03

This Precision Automatic Sharpener Grinding Machine has a max Grinding Length, up to 1500 mm. The area of its working bench is 1500*180(200) mm. The adjustable angle of the operating cutter table reaches ±90°. The power of the grinding head motor is 4 (unit as specified). Its total power is 6.5/5.5 (unit as specified). The reciprocating speed of grinding ranges from 0-20 mm/min. The machine size measures 4000*1500*1500 mm. The machine weight is 2000 kg.

| NAME | UNIT | PARAMETER |

| Max Grinding Length | MM | 1500 |

| Area of Working Bench | MM | 1500*180(200) |

| Adjustable Angle of Operating Cutter Table | MM | ±90° |

| Power of Grinding Head Motor | MM | 4 |

| Total Power | MM | 6.5/5.5 |

| Reciprocating Speed of Grinding Speed | MM/MIN | 0-20 |

| Machine size | MM | 4000*1500*1500 |

| Machine Weight | KG | 2000 |

ALVA strictly controls quality at every stage:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q1:What is the delivery time for the Grinding Machine?

A1: The standard delivery time for our Grinding Machine is 20-40 working days, depending on the factory’s production schedule and order volume. For urgent orders, we can expedite the process to ensure you receive your machine as soon as possible. We keep you informed at every stage of production and shipping, providing estimated delivery times upfront.

Q2:How is the machine installed and commissioned?

A2: We offer comprehensive installation support. Our engineers can visit your location to guide the installation and commissioning of the Grinding Machine. We provide detailed installation drawings, pit design diagrams, operating manuals, electrical manuals, maintenance manuals, and electrical wiring diagrams to ensure a smooth setup process.

Q3:What is the warranty period for the Grinding Machine?

A3:We provide a 1-year warranty for our Grinding Machine, excluding damage caused by human error or improper operation. Our quality control teams inspect every part from the design stage to the final completion of the machine to ensure the highest standards are met.

Q4:How is the quality of the Grinding Machine ensured?

A4: We ensure the highest quality by conducting rigorous inspections at every stage of production. Our products are certified by CE, ISO 9001:2015, and TUV, ensuring they meet international standards. Additionally, we perform production samples before mass production and final inspections before shipment.