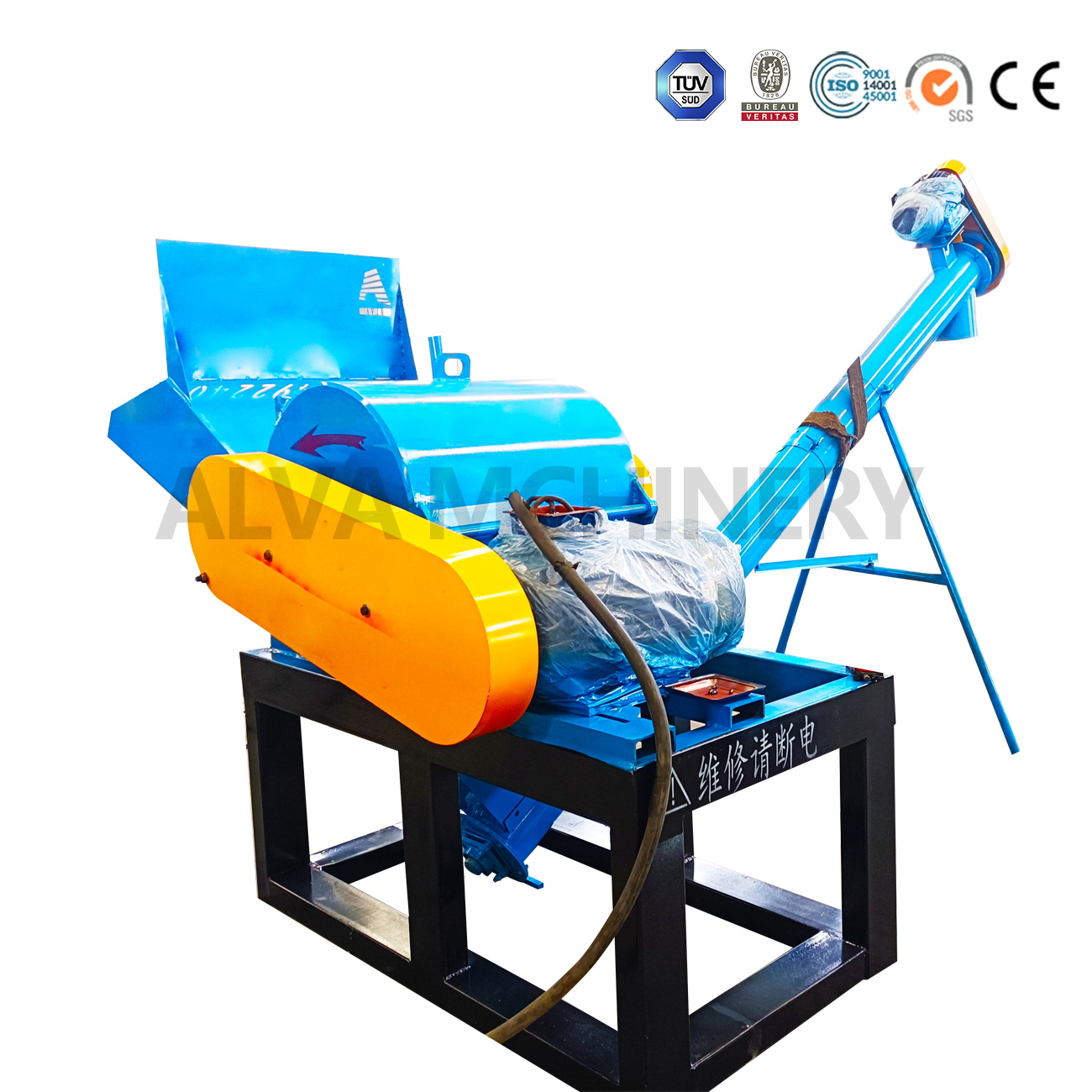

The manual PVC crusher has a large main shaft rotation diameter, a large crushing chamber capacity, and a unique blade shaft design that has a strong grip on hollow products. The shells are made of solid welded steel structures and have a wide range of versatility. Depending on the crushed material, there are different rotor designs, which can also crush gates, pipes, profiles, sheets, films, and large sprue materials. The machine has many advantages such as economy, durability, easy cleaning, and long service life. The blade material is wear-resistant and has high hardness. Large hollow plastics, hollow packaging boxes, plastic boxes, plastic frames, and home appliance shells can be directly crushed without flattening.

The Manual PVC Crusher is a portable, cost-effective solution for small-scale PVC recycling. Designed for manual operation, it efficiently crushes PVC pipes, profiles, and sheets into 8-16 mm granules , ideal for workshops, construction sites, and DIY enthusiasts. Its compact design and easy-to-use mechanism make it a sustainable choice for on-site waste reduction.

No external power source is required. The hand-cranked mechanism allows operator-controlled crushing, reducing dependence on electricity and lowering operational costs.

Built with a solid steel frame and D2 tool steel blades , the crusher withstands continuous use and heavy-duty loads. The adjustable blade depth accommodates thick PVC materials like pipes and boards.

The removable hopper and quick-release blade holders simplify cleaning and blade replacement. The rust-resistant coating ensures longevity in humid environments.

PVC Pipe Recycling: Processes used pipes, fittings, and tubing into recyclable pellets.

Plastic Scrap Reduction: Handles PVC sheets, window profiles, and packaging materials, reducing their volume by 70%+.

DIY Projects: Perfect for hobbyists and small businesses to recycle scrap PVC into custom parts.

Q: Can the Manual PVC Crusher handle rigid PVC?

A: Yes. Its D2 steel blades and adjustable pressure effectively crush rigid PVC without damaging the mechanism.

Q: What is the maximum feed size?

A: The hopper opening accepts materials up to 100 mm in diameter, such as PVC pipes and boards.

Q: Is it suitable for outdoor use?

A: Yes. The weather-resistant design and portable frame allow outdoor operation in construction sites and gardens.

|

Parameter |

Value |

|

Model |

Manual PVC Crusher |

|

Processing Capacity |

0.5-1 ton/hour |

|

Blade Material |

D2 Tool Steel |

|

Output Granule Size |

8-16 mm |

| Feed Size |

≤100 mm |

|

Weight |

80 kg |

| Dimensions |

800×600×1,200 mm |

01

The manual PVC crusher has a large main shaft rotation diameter, a large crushing chamber capacity, and a unique blade shaft design that has a strong grip on hollow products.

02

The shells are made of solid welded steel structures and have a wide range of versatility.

03

03

Depending on the crushed material, there are different rotor designs, which can also crush gates, pipes, profiles, sheets, films, and large sprue materials.

| Model | 180 | 250 | 300 | 400 |

| Crushing Capacity(KG/H) | 50-100 | 150-200 | 200-300 | 250-450 |

| Voltage | 3N-380V | |||

| Motor Power(KW) | 1.5/2.2 | 4 | 5.5 | 7.5 |

| Motor Power(HP) | 2/3 | 5.5 | 7.5 | 10 |

| Blade Quanlity | 9+2 | 6+2 | 9+2 | 12+2 |

| Rotation Diameter(MM) | 148 | 225 | 240 | 270 |

| Mesh Size(MM) | 6 | 8 | 8 | 10 |

| Feed Port Size(MM) | 110*180 | 250*160 | 320*200 | 420*220 |

| Dimension(MM) | 630*520*950 | 900*700*1050 | 1000*750*1180 | 1060*880*1320 |

| Weight(KG) | 120 | 230 | 330 | 430 |